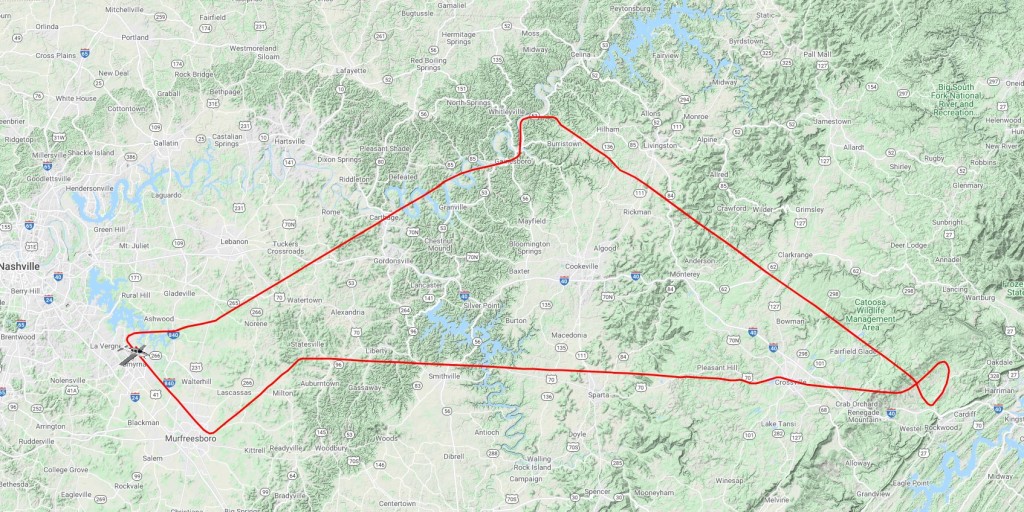

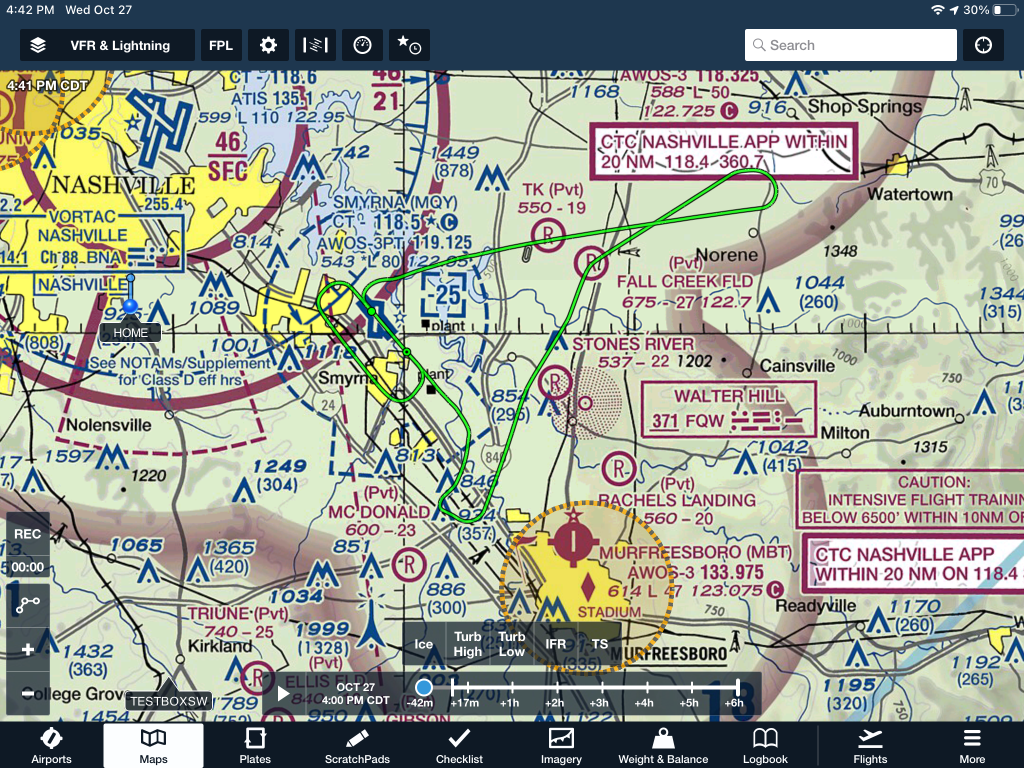

The final flight. As I have nothing else to test at this time, I decided to just make it a fun flight, to celebrate all the hard work that it took to come this far.

I departed runway 32 to the east, and then turned north. A beautiful day, blue skies and almost no turbulence, a nice way to end 10+ years before I could get to the beginning of the real mission of the aircraft. Many days, weeks, years of designing, building, and testing, we are now starting to enjoy the fruits of all that labor.

And not just my labor, but that of those that surrounded me and the hull. From neighbors that helped my turn the plane upside down, to Roy and his truck and trailer that I used to move the plane multiple times, to JD Upholstery, who as a team helped with, and installed the interior. Jimmy, who unfortunately passed last year will never be forgotten as we will enjoy his work for years to come.

Then there is Tim Hass with Approach Fast Stack, who helped put the Avionics package together, and who has helped me through a few technical issues through the years. Always quick with an answer.

While flying this amazing machine, I started to think of all the other VELO pilots, the ones on the VOBA, those who I met at OSH, Rough River or somewhere else, the Factory at Sebastian, especially Scott Swing, John Abraham, Ingrid, Chad, and especially Art, who had to deal with my nonsense and find the best person to talk to.

A good friend, Stephen Port, EAA member and my former Vice President, was instrumental in my painting endeavor. He helped me overcome my resistance to painting. I am not a painter, at all, and yet he gave me the hints I needed to prime the aircraft. I hope to lean on him when we finally put the final coats on.

The past years I had some big help from especially two friends, Aad Zeeuw and Howard Kohnstamm, who assisted me in the years of COVID to finish this project. Without them, I might still be in the hangar, trying to convince myself that someday it will be finished. They set a date, December 31, 2020. Although we didn’t make it, it surely helped with keeping the pressure on and pushing forward.

But the biggest thanks go out to , you guessed it, my family. Dana has been rolling her eyes through the years, about design questions I had for her, the plane in the garage being in the way, me late for dinner as I was attaching something and it had to happen now.. My kids, having pretty much grown up with a plane in the garage, having to explain to their friends about their dad building an airplane.. and some flying trips we have done in the meantime in other aircraft. Thank you !

All these people joined me in this last test flight, just finishing the last point 8 of and hour, to get past the 40 hrs required testing time. It is an accomplishment, they say, but they forget often it was because of them that I got it achieved. It’s always a Team Effort !

I owe all of you a flight.. until then, Thanks !

Patrick